How AI is Remaking Lithium-Ion Battery Recycling [Guest]

The Quiet Industrial Revolution: How Intelligent Systems Are Transforming Sustainability, Redefining Geopolitical Competition, and Unlocking New Economic Paradigms

It takes time to create work that’s clear, independent, and genuinely useful. If you’ve found value in this newsletter, consider becoming a paid subscriber. It helps me dive deeper into research, reach more people, stay free from ads/hidden agendas, and supports my crippling chocolate milk addiction. We run on a “pay what you can” model—so if you believe in the mission, there’s likely a plan that fits (over here).

Every subscription helps me stay independent, avoid clickbait, and focus on depth over noise, and I deeply appreciate everyone who chooses to support our cult.

PS – Supporting this work doesn’t have to come out of your pocket. If you read this as part of your professional development, you can use this email template to request reimbursement for your subscription.

Every month, the Chocolate Milk Cult reaches over a million Builders, Investors, Policy Makers, Leaders, and more. If you’d like to meet other members of our community, please fill out this contact form here (I will never sell your data nor will I make intros w/o your explicit permission)- https://forms.gle/Pi1pGLuS1FmzXoLr6

The transition to a sustainable future isn't just a vague hope; it's being built, piece by piece, with tangible innovations. Lithium-ion battery recycling is a critical strategic asset; understanding its evolution illuminates pathways not only to resource independence but to environmental sustainability, geopolitical leverage, and economic resilience. Few analysts combine deep industry expertise with strategic insight quite like

, someone I deeply respect for his ability to look past the headlines and present clear, sometimes contrarian, always useful analysis. As new hardware becomes the critical path- or bottleneck- for progress in AI, Quantum Computing, and other deep tech fields, sources Mith’s newsletter will be key to keeping up with the changes. Would strongly recommend checking it out.In today’s post, we will break down how AI is revolutionizing lithium-ion battery recycling, transforming it from a costly, risky process into a streamlined, sustainable, and strategically essential industry. The guest post covers ideas like precise automated sorting, optimized control of chemical reactions, predictive intelligence that averts operational disasters, and international competitive dynamics. Mith demonstrates clearly how intelligent applications systematically convert liabilities into strategic assets, highlighting how applied intellect can elevate industrial capabilities significantly.

As you read this post, I think the following questions are worth asking:

The Replicable Playbook for Value Capture: Many of the AI methodologies applied here- intelligent sorting, digital twin optimization, predictive safety- are not confined to batteries. Which other foundational industries could the disciplined application of these patterns unlock significant strategic value or expose critical vulnerabilities in incumbents? Which of them will be easiest to sell to? Which will be most lucrative? How will technological shifts lead to future restructing of existing industries- Mergers, Reshaping, etc?

What are the Dynamics of Dominance: China's advanced position in AI-driven recycling is established. Beyond policy or market scale, what does their progress reveal about differing philosophies of industrial AI adoption—perhaps a more decisive, even ruthless, risk appetite versus cautious, consensus-bound approaches elsewhere? What can be replicated, and what can’t?

Adaptability as the New Standard: Given diverse battery designs, could strategic advantage lie not in universal standardization but in cultivating profoundly adaptable AI systems capable of mastering evolving inputs? Essentially rendering design variation a tactical non-issue.

Digital Twins: Digital twins clearly offer significant conceptual power. What is the pathway- and key inflection points- for these systems to evolve from sophisticated advisory roles to autonomous agents exerting real-time sovereign control over complex recycling operations? Is that even something we want?

Foresight as Strategic Capital – Beyond Basic Safety: Beyond immediate risk mitigation, what cascading strategic benefits accrue to organizations fully integrating AI-driven predictive capabilities into their core operations? Which will be the first to happen, and which will be the most important.

Efficiency as Catalyst: How can efficiencies unlocked by AI strategically catalyze broader systemic transformations, such as aggressively displacing virgin material reliance or fundamentally reshaping product life-cycle economics?

Activating Dormant Economies: AI precisely assesses used battery viability. What further intelligent automation is necessary to unlock and scale a mainstream global market for second-life batteries, effectively creating a new asset class?

Would love to hear your answers here, or other questions you come up with. If you want to guest post on the newsletter, fill out our community introduction form, and I’ll reach out to you if there’s a match.

The rapid rise of electric vehicles (EVs) and renewable energy storage has led to a surge in demand for lithium-ion batteries (LIBs). This growth highlights the need for effective end-of-life (EoL) battery management. Efficient recycling is crucial for recovering valuable materials, reducing costs, and minimizing environmental impact. Artificial intelligence (AI) is revolutionizing LIB recycling by automating processes, enhancing precision, and promoting sustainability. AI is streamlining tasks from dismantling and sorting to process control, making recycling faster, more cost-effective, and environmentally responsible.

This article explores how AI is transforming each stage of LIB recycling, including automated dismantling, AI-driven sorting, and precise process control to recover metals like lithium, cobalt, and nickel. It also highlights the role of digital technologies, such as digital twins and data-driven decision-making, in optimizing the battery value chain. These innovations reduce material loss, lower energy consumption, and minimize chemical use, driving the transition to a circular economy. Additionally, it examines China’s leadership in AI-driven recycling and the potential of emerging technologies to further enhance sustainability and cost-efficiency.

Digital Twins and Virtual Twin Experiences for Efficient Recycling

Digital twins (DTs) and virtual twin experiences (VTEs) transform LIB recycling by creating digital models of physical systems. DTs provide virtual representations, while VTEs model entire systems, including environmental interactions, enabling comprehensive simulations. In recycling, VTEs could optimize disassembly, material recovery, and energy use, reducing costs and emissions.

For example, VTEs simulate battery disassembly to minimize material loss, supporting near-zero waste goals. They also optimize hydrometallurgical processes, reducing energy use and chemical inputs. In manufacturing, VTEs reduce scrap rates by simulating production steps. Integrated with AI and machine learning, VTEs predict second-life performance, ensuring recycled materials match virgin material quality.

VTEs enable “design-for-circularity,” promoting battery designs for easy disassembly and recycling. They also simulate supply chain dynamics, optimizing raw material choices to lower costs and environmental impact. Real-world data feedback creates closed-loop systems, enhancing circularity.

Data-Driven Decision-Making and Circular Economy

Digital tools, like centralized databases and semantic layers, streamline the complex LIB value chain. Projects such as KIproBatt and DataBatt use process-centric data models to enhance data management and enable AI applications. Data-driven campaigns and incentives boost battery collection, supporting urban mining for valuable materials.

Combining life-cycle assessment (LCA) with machine learning, manufacturers optimize battery designs for sustainability, reducing emissions and waste. Digital twins of manufacturing processes minimize defects, while recycling data informs eco-design for recyclability. With LIB waste projected to hit significant volumes by 2040, digitalization is vital for managing emerging technologies like all-solid-state batteries (ASSBs). Data-driven insights mitigate raw material depletion and environmental impacts, advancing a circular economy.

AI-Driven Dismantling and Diagnostics

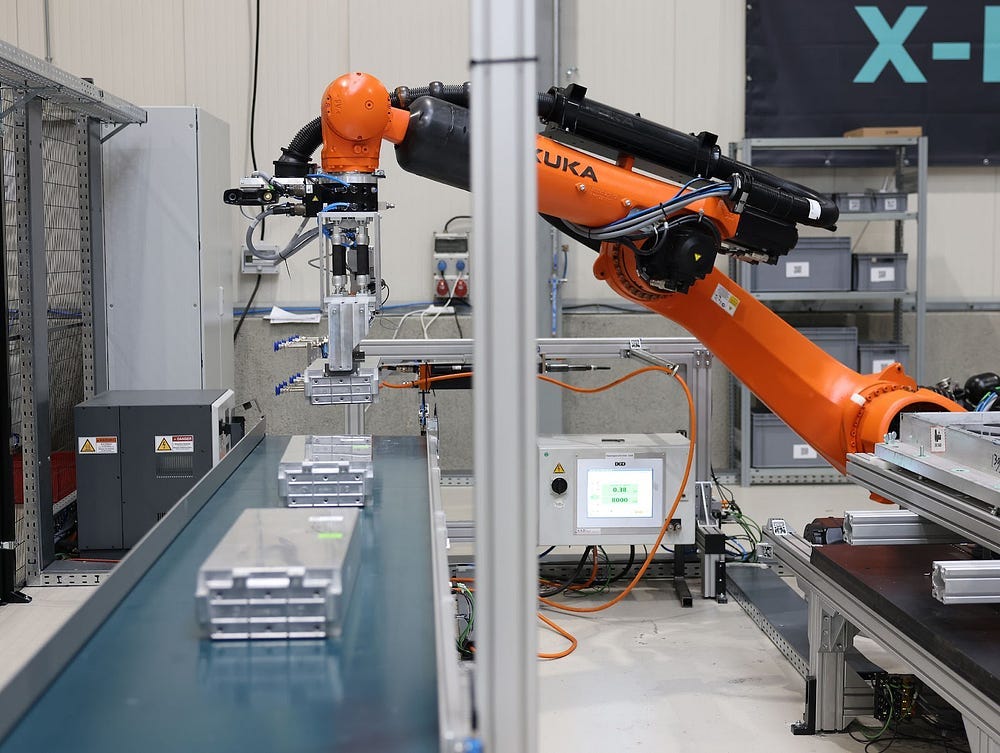

Automated dismantling is becoming a cornerstone of AI-driven LIB recycling. Circu Li-Ion, a European startup, exemplifies this with its AI-assisted disassembly and diagnostics system. Using advanced 3D cameras and robotics, their system achieves high precision in identifying and separating battery components. This reduces material loss and enables the identification of reusable cells for second-life applications.

Source: Circu Li-Ion — Demonstration model of their 2 kWh and above platform.

The process begins with a pre-diagnostic stage to assess and safely discharge battery packs. AI algorithms guide robotic arms to unscrew, remove lids, and extract modules, adapting to complex battery designs, including those with adhesives. Automation cuts labor costs, reduces energy consumption, and lowers chemical use in subsequent processes. By reducing CO2 emissions, AI-driven dismantling supports global sustainability goals and fosters a circular economy.

Digitalization enhances dismantling efficiency further by integrating sensors and data-driven tools. Machine learning combined with LCA enables optimized decisions on cell designs, minimizing environmental impact. Digital twins simulate dismantling sequences, identify inefficiencies, and reduce scrap rates, improving sustainability.

Optimizing Process Control in Recycling

AI’s impact extends to process control, particularly in hydrometallurgical processes for extracting valuable metals. AI optimizes variables like pH, temperature, and chemical concentrations, increasing metal recovery rates while reducing reagent use, energy consumption, and chemical waste. Real-time monitoring and adjustments ensure efficient operations, critical as global demand for lithium, cobalt, and nickel rises.

Digital tools, such as digital twins, enhance process control by simulating recycling workflows. These virtual models identify bottlenecks and optimize energy and chemical inputs, reducing costs and emissions. For example, digital twins can simulate hydrometallurgical processes to minimize waste, achieving up to 30% reductions in chemical use. Centralized databases that track material flows and incentivize collection further support transparency and collaboration, fostering a circular battery value chain.

Source Nth Cycle — Demonstration Plant — Fairfield — Produces Nickel Cobalt MHP

Examples of AI usage in the hydrometallugical stage.

Primobius: A joint venture involving Mercedes-Benz, Primobius uses AI-integrated robotics in its Kuppenheim, Germany facility to achieve 96% material recovery rates. Their hydrometallurgical process, guided by AI, minimizes chemical inputs, lowering costs and environmental impact.

Nth Cycle: This U.S.-based company leverages AI in its electro-extraction process to recover cobalt and nickel. The AI system optimizes electricity use, reducing energy consumption by 60% compared to pyrometallurgical methods, while achieving high purity outputs that reduce downstream chemical needs.

AI-Based Predictive Maintenance for Recycling Equipment to Prevent Catastrophic Failures

Recycling equipment in lithium-ion battery processing facilities faces significant wear due to the diverse and complex materials handled, making traditional reactive maintenance both costly and disruptive. AI-driven systems, integrating sensor data, historical records, and real-time metrics, can predict equipment failures before they occur, enabling proactive repairs. By analyzing patterns in equipment performance, AI identifies potential issues, such as worn components or inefficiencies in gas collection systems, allowing maintenance teams to address them during scheduled downtimes. This approach reduces unplanned outages, lowers repair costs, and ensures smoother operations, which is critical as global EoL battery volumes are projected to surge by 2030.

Critical Mineral Recovery’s lithium-ion battery recycling plant near Fredericktown, Missouri.

In 2024, a lithium-ion battery recycling facility in Fredericktown, Missouri suffered a catastrophic fire, likely caused by a hydrogen vapor cloud igniting during an inert atmosphere shredding stage. The facility’s shredding platfrom managed gases released during thermal runaway — an exothermic reaction producing hydrogen, ethane, and methane — but a failure in gas containment led to the disaster. There were reports after the fire that some workers felt ill shortly before what has been described as an explosion and a fireball, highlighting safety risks. AI, combined with machine learning (ML) and digital twins, could have mitigated this by monitoring gas concentrations in real time via chemical sensors. A digital twin, simulating the shredding process, could compare live data against expected outcomes, detecting anomalies like elevated hydrogen levels and triggering automated responses, such as pressure adjustments or emergency shutdowns, to prevent ignition.

This was not the first or even the second time a fire had broken out at one of the company’s facilities — it was the third. This is clear evidence that the industry standard of analog systems coupled with human monitoring is inadequate for addressing the safety issues in lithium-ion battery recycling. The company has ceased all operations as federal agencies, including the EPA, conduct reviews of the events leading up to this disaster.

By averting catastrophic failures, AI-driven predictive maintenance enhances workplace safety and cost efficiency by identifying failure points early. For instance, AI could have flagged anomalies in the gas scrubbing systems or shredding equipment, directing personnel to address specific issues before they escalated into hazardous situation. This proactive approach also minimizes the need for reactive maintenance in dangerous environments, reducing risks to workers and improving operational reliability. By leveraging real-time data and predictive analytics, AI not only prevents accidents but also optimizes resource allocation, cutting maintenance costs and supporting the scalability of battery recycling as demand for sustainable solutions grows.

AI in Lithium-Ion Battery Recycling: China’s Advancements

China, holding a significant share of global LIB recycling capacity, leads in AI-driven recycling, fueled by robust policies and a thriving EV market. Chinese firms leverage AI for dismantling, sorting, and material recovery, achieving significant cost savings and environmental benefits.

Suzhou Botree Cycling Sci & Tech Co., Ltd.: Botree’s AI-driven sorting and recovery systems achieve high recovery rates for lithium, nickel, and cobalt. Computer vision categorizes batteries by chemistry, minimizing material loss, wastewater, and energy use.

Henan Hairui Intelligent Technology: Hairui employs AI-powered machine learning and robotic disassembly to handle diverse battery formats, cutting costs and environmental impact.

Hunan Brunp Recycling Technology Co., Ltd.: A CATL subsidiary, Brunp processes large volumes of LIBs annually using AI-driven robotic disassembly, reducing material loss and chemical use.

Ganzhou Highpower Technology Co., Ltd.: Highpower’s AI sorting systems deliver high accuracy in material separation, lowering recycling costs and energy consumption.

China’s policies, including standards for black mass and automation subsidies, accelerate AI adoption. A 2024 study forecasts that AI-driven recycling could significantly reduce lithium, cobalt, and nickel demand while cutting carbon emissions. Challenges like coal-heavy energy grids and non-standardized battery designs persist, increasing costs.

Integration of Redux Recycling’s AI and Automation Systems by Redwood Materials

In September 2023, Redwood Materials acquired Redux Recycling GmbH to enhance its lithium-ion battery (LIB) recycling capabilities. Redux operates a facility in Bremerhaven, Germany, processing 10,000 tonnes of batteries annually from EVs, e-bikes, and consumer electronics. The facility achieves high recovery rates for lithium, cobalt, nickel, and manganese.

Source: Redwood Materials — Super Sacks contain up to 1 tonne of consumer electronics with lithium-ion batteries.

The recycling process includes automated sorting, discharge, robotic disassembly for EV packs, thermal pretreatment, and mechanical separation to produce high-purity black mass. Redux’s sorting line utilizes near-infrared (NIR) spectroscopy and X-ray fluorescence (XRF) scanners to separate components like stainless steel, aluminum, copper, and active materials with high precision across cylindrical, prismatic, and pouch cells. A secondary vibratory screening stage recovers fine particulates, reducing material loss and labor costs compared to manual methods.

A dedicated team works with Saubermacher, an international waste management and recycling company based in Austria. Saubermacher specializes in sustainable waste management and resource recovery and operates in over 1,600 municipalities across several European countries. Saubermacher established Redux Recycling GmbH in 2016 to focus on the recycling of lithium-ion batteries. Following Redwood’s acquisition, the relationship with Saubermacher continues, as they assist in operating the systems at Redux’s facility, reducing energy consumption and minimizing chemical inputs in hydrometallurgy, in line with industry standards.

Redwood plans to integrate Redux’s automation with its Reductive Calcination and hydrometallurgical refining to produce cathode active materials, enabling scalable processing to meet U.S. EV battery demand.

Optimizing Lithium-Ion Battery Recycling with A Digital Enterprise Framework

Siemens’ Digital Enterprise framework integrates digital twins, data analytics, and automation systems to optimize recycling operations, enabling efficient recovery of materials like lithium, cobalt, and nickel. These technologies help manage the growing volume of used batteries from EVs while reducing energy consumption and environmental impact compared to traditional labor-intensive recycling methods. Siemens’ systems support precise material separation and hydrometallurgical processes, essential for handling complex battery chemistries safely and effectively.

Source: Siemens — Six Acts of a Digital Twin

The Totally Integrated Automation (TIA) portfolio is being used in next-generation recycling solutions, enabling the creation of automated production lines that balance speed, cost, and quality in material recovery. Siemens is collaborating with the American Battery Technology Company (ABTC) to advance recycling processes, focusing on sustainable methods to recover battery-grade materials for their South Carolina lithium-ion recycling facility that is under development now. This partnership leverages Siemens’ automation expertise to enhance ABTC’s recycling operations, improving efficiency and scalability. Siemens also works with other partners, such as AESC, to reduce waste and improve efficiency by implementing automated technologies, contributing to the development of a circular economy for batteries.

Siemens’ Xcelerator platform provides digital tools for designing and testing recycling processes virtually, helping to reduce errors and optimize resource use. Their IoT-enabled systems and smart infrastructure support recycling facilities in meeting environmental regulations and minimizing waste. Additionally, Siemens engages in educational initiatives, such as partnerships with USC, to train professionals in digital tools. Through these efforts, Siemens addresses the technical and operational challenges in the lithium-ion battery industry, supporting an industry expected to grow as demand for sustainable battery solutions increases.

The Future of Automation in Lithium-Ion Recycling

AI-driven LIB recycling is poised for growth, driven by emerging technologies and global sustainability goals. By 2035, AI and digitalization could significantly cut recycling costs and greenhouse gas emissions.

Emerging Technologies: Advanced robotics with deep learning will boost disassembly efficiency, while AI-powered digital twins will optimize energy and chemical inputs in real time.

Global Trends and Challenges: Europe and the U.S. are advancing, spurred by recycled content standards and investments, but non-standardized battery designs and carbon-intensive energy grids pose challenges.

Future Outlook: The LIB recycling market is projected to reach significant value by 2034, led by companies like Circu Li-Ion, Siemens, and Botree Recycling. Near-closed-loop systems will minimize material loss, reducing the carbon footprint of battery production.

Conclusion

AI and digital technologies are fundamentally transforming lithium-ion battery (LIB) recycling, driving efficiency, cost savings, and sustainability across the value chain. From AI-powered dismantling and sorting, as demonstrated by innovators like Circu Li-Ion and China’s Botree Recycling, to advanced process control and predictive maintenance, these technologies are reducing material loss, energy consumption, and environmental impact. Digital tools, including digital twins and virtual twin experiences, further optimize recycling workflows, enabling near-zero waste and supporting a circular economy.

Source: Siemens- At the SPS trade fair in Germany in November, Siemens presented a scalable robot demo developed by Schmid’s team, which enables automatic disassembly of an electric car’s battery.

While China leads with its robust AI-driven recycling ecosystem, Western companies like Redwood Materials and ABTC are rapidly advancing, narrowing the technological gap. As emerging technologies evolve and global demand for LIBs grows, AI and digitalization will play a central role in scaling sustainable recycling practices, minimizing local resource depletion, and supporting a cleaner energy future.

DISCLAIMER: This article should not be construed as an offering of investment advice, nor should any statements (by the author or by other persons and/or entities that the author has included) in this article be taken as investment advice or recommendations of any investment strategy. The information in this article is for educational purposes only. The author did not receive compensation from any of the companies mentioned to be included in the article.

References:

https://www.mckinsey.com/capabilities/operations/our-insights/what-is-digital-twin-technology

https://ec.europa.eu/commission/presscorner/detail/en/ip_22_7657

https://www.circu-li-ion.com/

https://www.botree-cycling.com/

http://www.hnhairui.com/

http://www.brunp.com.cn/

http://www.highpowertech.com/

https://www.redwoodmaterials.com/

https://www.nfpa.org/news-blogs-and-articles/blogs/2024/11/01/missouri-battery-plant-fire

Thank you for being here, and I hope you have a wonderful day.

Dev <3

I provide various consulting and advisory services. If you‘d like to explore how we can work together, reach out to me through any of my socials over here or reply to this email.

I put a lot of work into writing this newsletter. To do so, I rely on you for support. If a few more people choose to become paid subscribers, the Chocolate Milk Cult can continue to provide high-quality and accessible education and opportunities to anyone who needs it. If you think this mission is worth contributing to, please consider a premium subscription. You can do so for less than the cost of a Netflix Subscription (pay what you want here).

If you liked this article and wish to share it, please refer to the following guidelines.

That is it for this piece. I appreciate your time. As always, if you’re interested in working with me or checking out my other work, my links will be at the end of this email/post. And if you found value in this write-up, I would appreciate you sharing it with more people. It is word-of-mouth referrals like yours that help me grow. You can share your testimonials over here. The best way to share testimonials is to share articles and tag me in your post so I can see/share it.

Reach out to me

Use the links below to check out my other content, learn more about tutoring, reach out to me about projects, or just to say hi.

Small Snippets about Tech, AI and Machine Learning over here

AI Newsletter- https://artificialintelligencemadesimple.substack.com/

My grandma’s favorite Tech Newsletter- https://codinginterviewsmadesimple.substack.com/

Check out my other articles on Medium. : https://rb.gy/zn1aiu

My YouTube: https://rb.gy/88iwdd

Reach out to me on LinkedIn. Let’s connect: https://rb.gy/m5ok2y

My Instagram: https://rb.gy/gmvuy9

My Twitter: https://twitter.com/Machine01776819

Brilliant deep dive. Thanks for publishing 🌟

I have big hopes for materials research at the intersection of AI and Quantum computing.